CNC Precision Engineering Versus Traditional Machining A Comprehensive Comparison

In the rapidly evolving world of manufacturing, the debate between CNC precision engineering and traditional machining has garnered increasing attention. CNC precision engineering, with its ability to produce intricate components with unparalleled accuracy and repeatability, offers a modern solution to many industries seeking to enhance productivity and minimize waste. Conversely, traditional machining methods, which have stood the test of time, still hold a significant place due to their simplicity and suitability for certain applications. This blog aims to provide a comprehensive comparison of these two approaches, exploring their respective advantages, disadvantages, and ideal scenarios for use. By understanding the capabilities and limitations of CNC precision engineering versus traditional machining, manufacturers can make informed decisions that best align with their project requirements and operational goals.

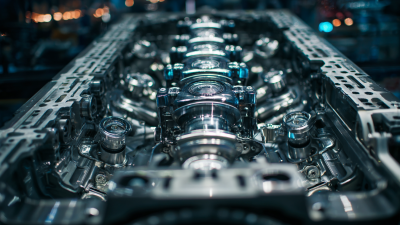

CNC Precision Engineering: An Overview of Key Benefits

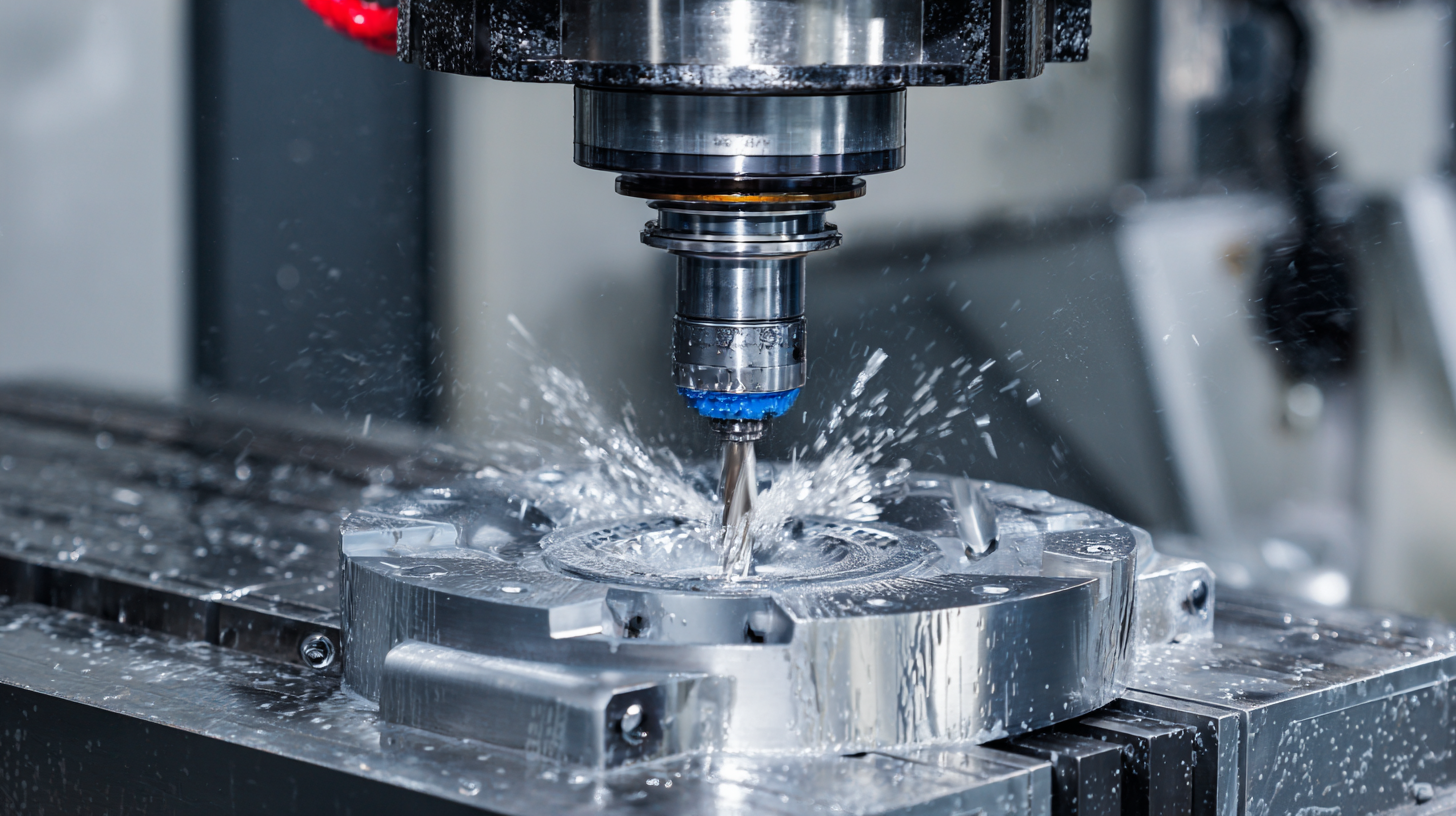

CNC precision engineering is revolutionizing the manufacturing landscape, offering distinct advantages over traditional machining methods. One of the key benefits of CNC technology is its ability to achieve high levels of accuracy and repeatability. This precision ensures that each component produced meets stringent specifications, which is particularly crucial in industries like aerospace and medical devices.

Additionally, CNC machines can operate continuously with minimal human intervention, leading to increased productivity. They are capable of executing complex designs that would be challenging or impossible with traditional methods. This versatility means manufacturers can respond quickly to changing market demands, producing customized solutions without compromising quality.

**Tips for Maximizing CNC Precision:**

1. Regularly calibrate your CNC machines to maintain accuracy and prevent deviations in production.

2. Implement a robust maintenance schedule to ensure all components are functioning optimally, which helps to prolong machine life and efficiency.

3. Invest in high-quality materials and tooling, as this can significantly impact the final product's precision and overall performance.

CNC Precision Engineering vs Traditional Machining

This chart illustrates a comparison between CNC Precision Engineering and Traditional Machining based on several key factors including accuracy, production speed, cost efficiency, and flexibility. The data demonstrates that CNC Precision Engineering often outperforms Traditional Machining in most areas.

Traditional Machining: Process and Applications Explained

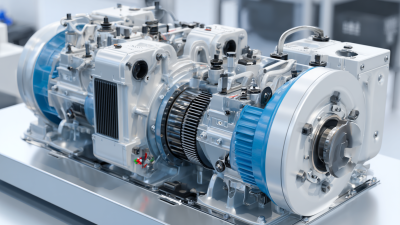

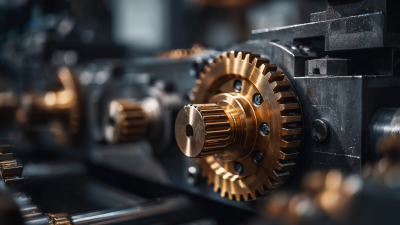

Traditional machining encompasses various processes that have been fundamental to manufacturing for centuries. Techniques such as turning, milling, drilling, and grinding are widely used to shape materials into desired forms. Each process involves removing material from a workpiece, making it essential for producing precision parts in numerous industries ranging from aerospace to automotive. Key applications of traditional machining include creating complex components, prototypes, and custom pieces that demand high levels of accuracy.

Traditional machining encompasses various processes that have been fundamental to manufacturing for centuries. Techniques such as turning, milling, drilling, and grinding are widely used to shape materials into desired forms. Each process involves removing material from a workpiece, making it essential for producing precision parts in numerous industries ranging from aerospace to automotive. Key applications of traditional machining include creating complex components, prototypes, and custom pieces that demand high levels of accuracy.

When considering traditional machining, it's crucial to remember a few tips to optimize your results. First, always select the right tool material; carbide tips, for instance, are ideal for hard materials, while high-speed steel is effective for softer metals. Additionally, ensure your machine settings are calibrated accurately to minimize errors during operation. Lastly, regular maintenance of your equipment can extend its lifespan and improve the overall quality of your workpieces. By keeping these pointers in mind, you can enhance your traditional machining processes and achieve superior results.

Cost Efficiency: Comparing CNC and Traditional Machining

In the realm of manufacturing, cost efficiency remains a pivotal factor influencing the choice between CNC precision engineering and traditional machining. According to a report by Grand View Research, CNC machining can reduce production costs by up to 40% compared to conventional methods due to its automated processes and reduced labor costs. The automation inherent in CNC technology not only streamlines production but also minimizes human error, leading to significant savings over time.

Moreover, traditional machining often incurs higher operational costs due to setup times and the need for skilled labor. The National Institute of Standards and Technology (NIST) reported that companies relying on traditional machining face an average downtime of 20-30% during setup and changeover, which further inflates overall costs. Conversely, CNC machining's efficiencies can lead to a 50% reduction in cycle times, making it a more economically sound option for high-volume production runs. As businesses strive to optimize their operations, the cost benefits of CNC machining continue to position it as the preferred choice in the competitive landscape of manufacturing.

CNC Precision Engineering Versus Traditional Machining: A Comprehensive Comparison - Cost Efficiency

| Criteria | CNC Precision Engineering | Traditional Machining |

|---|---|---|

| Setup Costs | High (due to equipment and programming) | Moderate (mostly labor and tooling) |

| Material Waste | Low (efficient cutting paths) | High (more manual adjustments) |

| Production Speed | High (automated processes) | Moderate (dependent on manual skill) |

| Labor Costs | Lower (fewer operators needed) | Higher (more skilled labor required) |

| Flexibility for Design Changes | High (easily reprogrammable) | Low (time-consuming to reconfigure) |

| Accuracy | Very High (consistent precision) | Moderate (depends on operator skill) |

| Maintenance Costs | Moderate (regular software updates) | High (more frequent repairs) |

Precision and Accuracy: How CNC Outperforms Traditional Methods

In the realm of manufacturing, precision and accuracy are paramount, and this is where CNC (Computer Numerical Control) machining distinctly outshines traditional methods. According to a report by the National Institute of Standards and Technology (NIST), CNC machining can achieve tolerances of up to ±0.005 mm, significantly surpassing the ±0.1 mm tolerance typical in conventional machining processes. This high level of precision is critical in industries such as aerospace and medical device manufacturing, where even the slightest deviation can lead to catastrophic failures.

Moreover, CNC machines are equipped with advanced software that enables complex geometrical designs and repeatability that are often unattainable via traditional machining. A study by the American Society for Quality (ASQ) found that the efficiency of CNC processes increased by approximately 30% due to automation and the ability to quickly adapt designs without changing the physical setup. This not only streamlines production but also reduces human error, thus enhancing overall accuracy. As manufacturers continue to prioritize operational efficiency and product quality, the shift towards CNC technology becomes increasingly apparent.

Flexibility and Scalability: Adapting to Market Demands in CNC vs Traditional Machining

The flexibility and scalability of CNC machining systems are revolutionizing manufacturing processes, particularly in today's dynamic market environment. According to recent industry reports, CNC machines can be reconfigured quickly to accommodate fluctuating demand, which significantly enhances production efficiency. For instance, the Ford Windsor Engine Plant, with its arrangement of approximately 120 CNC machines, exemplifies how a reconfigurable system architecture can adapt to changing production needs without extensive downtime. This adaptability allows manufacturers to maintain competitiveness, responding swiftly to market shifts.

Meanwhile, the integration of artificial intelligence (AI) into CNC machining is set to further transform these processes. Studies indicate that AI-driven advancements can optimize machining cycles, reduce waste, and enable predictive maintenance, leading to increased productivity and cost savings. The adoption of IoT technologies alongside CNC systems is also pivotal, as it provides real-time data analytics that facilitate informed decision-making and better resource allocation. As manufacturers leverage these advancements, traditional machining methods may struggle to keep pace, highlighting the importance of innovation in maintaining industry relevance.

Related Posts

-

Maximizing Savings with Superior After Sales Support for Best Mechanical Electrical Solutions

-

Unveiling Secrets to Source Premium Suppliers in Best Machine Engineering

-

Innovative Applications of Best Mechanical Engineering Tech in Modern Industries

-

China's Quality Evolution in Automotive Mechanical Engineering Driving Global Demand

-

Comparative Analysis of Civil Engineering Machines Efficiency in Modern Construction Projects

-

Top Strategies for Maximizing Efficiency with Best Civil Engineering Machines