How to Enhance Your Supply Chain with Mechanical Engineering Tech Solutions

In today's fast-paced business environment, enhancing supply chain efficiency has become a critical focus for companies aiming to remain competitive. Recent studies indicate that organizations utilizing advanced mechanical engineering tech solutions can improve their supply chain operations by as much as 30%, significantly reducing costs and improving delivery times. According to a report by the McKinsey Global Institute, the adoption of automation and mechanical engineering innovations could increase productivity in supply chains by 50% across sectors. As businesses navigate challenges such as demand fluctuations and supply disruptions, integrating mechanical engineering tech not only enables a more resilient supply chain but also fosters innovation and sustainability. By leveraging these advanced technologies, companies can optimize their processes, enhancing overall performance and customer satisfaction.

Leveraging Mechanical Engineering to Streamline Supply Chain Processes

In today's fast-paced business environment, streamlining supply chain processes is essential for maintaining competitive advantage. Leveraging mechanical engineering solutions can significantly enhance efficiency and reduce costs throughout the supply chain. By integrating advanced engineering technologies, companies can optimize their logistics and production systems, ensuring smoother operations from sourcing materials to final delivery.

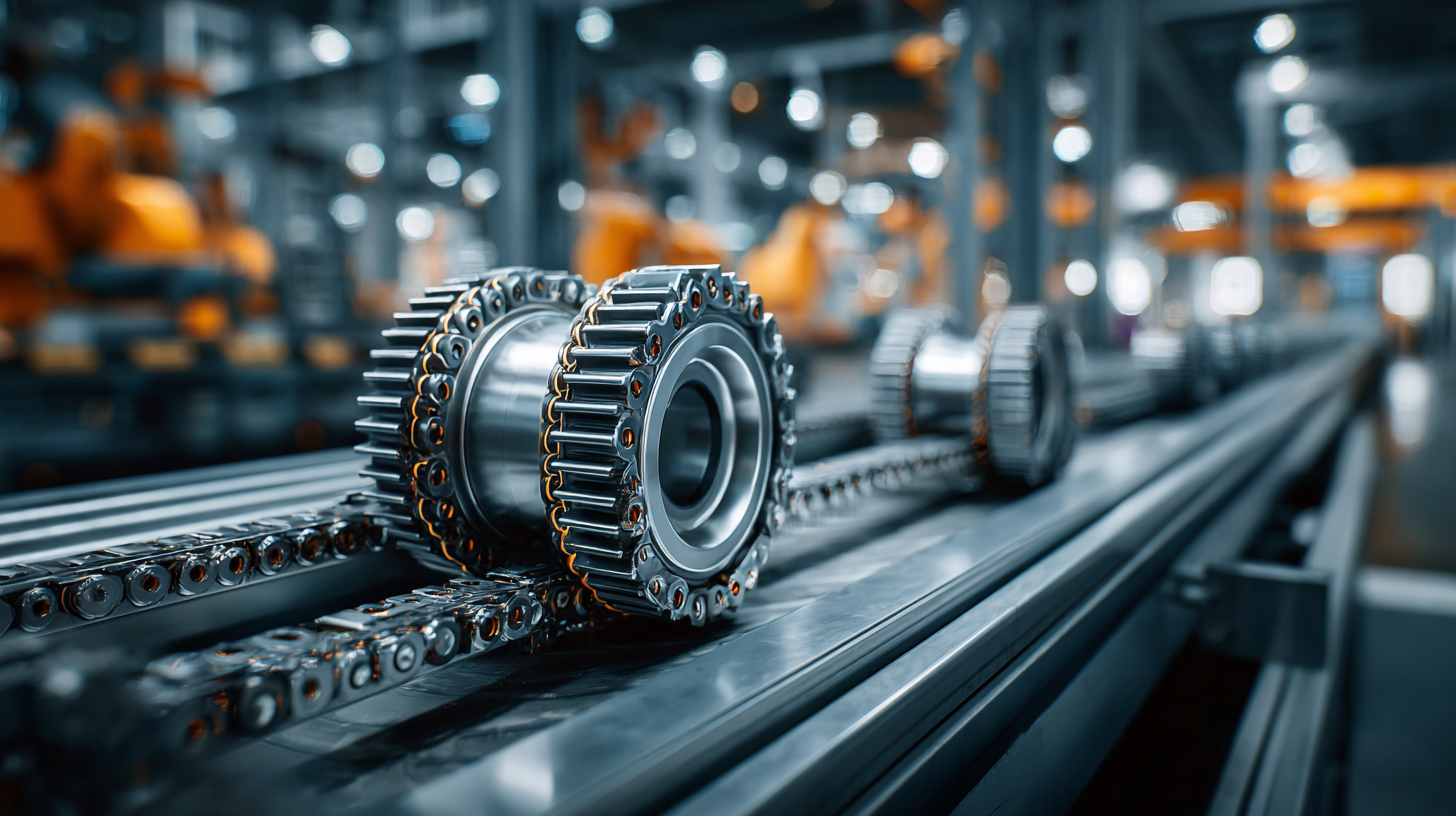

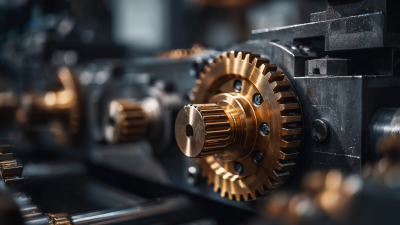

One key area where mechanical engineering can make a difference is in automation and robotics. Implementing automated systems for material handling and inventory management not only speeds up operations but also minimizes human error. Additionally, specialized mechanical solutions, such as predictive maintenance technologies, allow businesses to anticipate equipment failures before they occur, thereby reducing downtime and improving overall productivity. These advancements can lead to a more responsive supply chain capable of adapting to market demands swiftly.

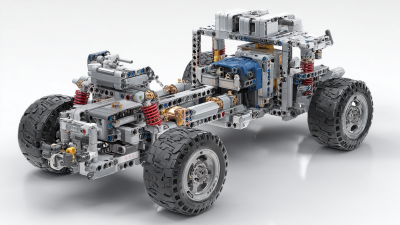

Moreover, the application of mechanical engineering principles in design and manufacturing processes can yield products that are not only more durable but also easier to assemble and transport. Innovations such as modular design enable companies to streamline production cycles and enhance flexibility in responding to changing customer preferences. By adopting these mechanical engineering technologies, businesses can create a more resilient supply chain that drives efficiency and boosts customer satisfaction in an increasingly competitive landscape.

How to Enhance Your Supply Chain with Mechanical Engineering Tech Solutions

| Dimension | Current Status | Proposed Mechanical Engineering Solutions | Expected Outcome |

|---|---|---|---|

| Inventory Management | Manual tracking, high discrepancies | Automated inventory tracking systems | Increased accuracy, reduced stockouts |

| Logistics Optimization | Traditional route planning | AI-based routing algorithms | Reduced delivery times, lower fuel costs |

| Quality Control | Manual inspections with human error | Automated inspection machinery | Higher product quality, consistent standards |

| Supplier Collaboration | Limited communication channels | Integrated communication platforms | Stronger relationships, faster feedback loops |

| Production Scheduling | Static scheduling methods | Dynamic scheduling tools | Improved efficiency, better resource utilization |

Integrating Smart Technologies for Real-Time Supply Chain Monitoring

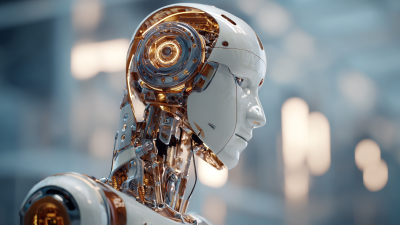

In today’s fast-paced market, integrating smart technologies into your supply chain is essential for achieving real-time monitoring and optimization. By leveraging mechanical engineering tech solutions, businesses can enhance visibility across their supply chain operations. Implementing Internet of Things (IoT) devices allows for the collection of critical data from various points, enabling managers to track inventory levels, monitor equipment performance, and predict potential disruptions.

**Tip**: Invest in a robust data analytics platform that can process the data gathered from your IoT devices. This platform should provide actionable insights that help streamline your logistics and improve decision-making processes.

Another effective way to enhance your supply chain is through the use of automated robotics in manufacturing and warehousing. These machines not only speed up production but also minimize errors. With the integration of sensors and AI, they can adapt to changes in real time, allowing for a more agile response to market demands.

**Tip**: Regularly update your technology stack to ensure compatibility with new tools and protocols. This will help maintain seamless communication between different systems and enhance the overall efficiency of your supply chain operations.

Optimizing Inventory Management with Mechanical Engineering Innovations

In today's rapidly evolving market, companies are increasingly turning to mechanical engineering innovations to optimize their inventory management. A report from the International Journal of Production Economics highlights that leveraging advanced mechanical technologies can reduce inventory holding costs by up to 30%. This reduction is primarily attributed to the improved accuracy in demand forecasting and automated inventory tracking systems that mechanical engineering serves to enhance.

Moreover, integrating robotics and automation into inventory management is proving invaluable. Research by McKinsey & Company indicates that automating warehousing operations can enhance productivity by 40% while also lowering labor costs significantly. These innovations provide real-time analytics, allowing businesses to respond quickly to changes in demand, thereby minimizing overstock and stockouts. Incorporating mechanical engineering solutions not only streamlines operations but also fosters a proactive approach to managing inventory, ultimately leading to greater overall efficiency in the supply chain.

Reducing Production Costs through Advanced Mechanical Solutions

In today's competitive market, manufacturers are continually seeking ways to reduce production costs while maintaining quality. Advanced mechanical engineering solutions offer innovative approaches to streamline operations. By integrating cutting-edge technologies such as automation, robotics, and predictive maintenance, businesses can significantly minimize waste and resource usage.

For instance, automated systems can optimize assembly lines, ensuring that products are assembled faster and with fewer errors, thereby lowering labor costs and increasing throughput.

Another crucial aspect is the implementation of robust design principles that focus on durability and efficiency. Mechanical engineering solutions can enhance product designs to reduce material consumption without compromising strength. Techniques such as virtual prototyping and simulation allow engineers to test and refine designs digitally, leading to cost-effective manufacturing processes.

Furthermore, investing in energy-efficient machinery not only cuts operational costs but also aligns with sustainable practices, ultimately contributing to overall savings in the supply chain. By leveraging these advanced mechanical solutions, companies can create a more agile and cost-effective production environment.

Enhancing Collaboration Across Supply Chain Stakeholders with Tech Tools

In today's fast-paced market, enhancing collaboration among supply chain stakeholders is crucial for achieving operational efficiency and resilience. Implementing technology tools can streamline communication and foster a collaborative environment, allowing all parties to work towards common objectives. Tools such as cloud-based platforms enable real-time data sharing, which helps in tracking inventory levels, production schedules, and shipment statuses, reducing delays and misunderstandings.

Tip: Invest in collaborative software that integrates seamlessly with your existing systems. This ensures that all stakeholders—from suppliers to logistics providers—can access pertinent information simultaneously, enabling informed decision-making.

Moreover, embracing advanced analytics can significantly improve stakeholder collaboration. By analyzing data trends and performance metrics, stakeholders can identify inefficiencies and potential bottlenecks within the supply chain. This proactive approach not only enhances transparency but also builds trust among partners.

Tip: Conduct regular training sessions on the latest technology tools and data analysis practices. This will empower your team members and partners to leverage these resources effectively, promoting a culture of collaboration and continuous improvement.

Related Posts

-

The Ultimate Guide to Discovering the Best Engineering Solutions for Your Business Needs

-

Unveiling Secrets to Source Premium Suppliers in Best Machine Engineering

-

Top Trends in Best Machine Engineering: What to Expect in 2025

-

Innovative Applications of Best Mechanical Engineering Tech in Modern Industries

-

Addressing the Key Challenges in the Performance of Civil Engineering Machines: A Data-Driven Approach

-

What is the Impact of Mechanical and Electrical Engineering on Modern Industries