The Evolution of Civil Engineering Machines Shaping Tomorrow's Infrastructure

In the ever-evolving landscape of infrastructure development, the role of civil engineering machines has become increasingly pivotal. As we stand on the brink of a new era in construction and urban planning, these machines are not merely tools; they are the backbone of innovation, efficiency, and sustainability. This blog delves into the alternatives in civil engineering machinery that are transforming the way we approach infrastructural challenges. From automated excavation systems to advanced material handling equipment, the integration of cutting-edge technology into civil engineering machines is reshaping our built environment. As cities expand and the demand for resilient infrastructure grows, understanding these alternatives is crucial for engineers and planners alike. Join us as we explore how these remarkable advancements are not only enhancing construction practices but also paving the way for a sustainable future.

The Historical Development of Civil Engineering Machines

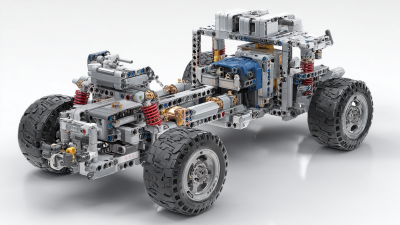

The evolution of civil engineering machines traces back to ancient civilizations, where rudimentary tools laid the groundwork for modern construction. Early engineers utilized simple levers, pulleys, and inclined planes made from wood and stone to manipulate heavy materials. The Roman Empire significantly advanced these techniques with the development of the crane, which enabled the construction of monumental structures like aqueducts and amphitheaters. These innovations reflected a growing understanding of physics and material science, paving the way for more complex machinery.

As the Industrial Revolution took hold in the 18th and 19th centuries, machines began to evolve at an unprecedented pace. The steam engine revolutionized transportation and construction, leading to the introduction of steam shovels and pile drivers. These powerful machines allowed for the rapid excavation and foundation work necessary for burgeoning urban landscapes. By the 20th century, advancements in hydraulics and electronics further transformed civil engineering machines, resulting in the modern excavators, bulldozers, and cranes we see today. Each stage of development illustrates humanity's ingenuity and adaptability, laying a solid foundation for the ambitious infrastructure projects of tomorrow.

Innovative Technologies Revolutionizing Construction Equipment

At CES 2025, innovative technologies took center stage as concepts for lunar construction machinery were revealed, marking a significant leap in the evolution of civil engineering machines. These futuristic designs aim to tackle the unique challenges of building infrastructure on the Moon and other celestial bodies. The emphasis on underwater automation aligns with the growing need for advanced construction solutions that can operate in extreme environments, showcasing the endless possibilities for construction equipment in the unexplored realms of our universe.

Collaboration between nations is also driving innovation in construction technology. A partnership between Ukraine and Japan has emerged, focusing on the development of remote-controlled construction equipment. This groundbreaking initiative not only aims to enhance recovery efforts but also emphasizes veteran reintegration and inclusivity in the workforce. By utilizing remote-controlled technologies, construction tasks can be performed safely and efficiently, paving the way for a new era of construction that prioritizes both technological advancement and social responsibility. As these innovations reshape the industry, they highlight the potential for civil engineering machines to not only build our infrastructure but also to explore and understand new frontiers.

Sustainability in Modern Civil Engineering Machinery

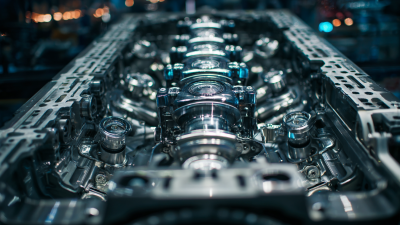

In recent years, the civil engineering industry has significantly shifted its focus towards sustainability, leading to the emergence of advanced machinery designed for eco-friendly construction practices. According to a report by the World Economic Forum, the global construction industry contributes approximately 38% of total greenhouse gas emissions. As a response, manufacturers are integrating electric and hybrid technologies into heavy machinery, which not only reduces emissions but also enhances energy efficiency. For instance, electric excavators can cut energy consumption by up to 50% compared to their diesel counterparts, showcasing a promising shift towards greener alternatives.

Furthermore, the adoption of innovative materials and methods is revolutionizing how infrastructure is built and maintained. The use of 3D printing in civil engineering projects has become a game-changer, allowing for the creation of structures with minimal waste. The Global Robotics Institute reports that the integration of robotics can reduce labor costs by as much as 40% while promoting safety on site. Additionally, sustainable machinery features such as optimized fuel consumption and recyclable materials in their construction align with the growing demand for environmentally responsible practices, helping the civil engineering sector to not only meet regulatory requirements but also to satisfy the increasing societal demand for sustainability.

The Evolution of Civil Engineering Machines Shaping Tomorrow's Infrastructure - Sustainability in Modern Civil Engineering Machinery

| Machine Type | Sustainability Features | Efficiency Rating (out of 10) | Applications | Carbon Emissions Reduction (%) |

|---|---|---|---|---|

| Excavator | Electric powered, Reduced noise | 9 | Earthmoving, Digging | 30 |

| Dump Truck | Hybrid system, Fuel-efficient | 8 | Material transportation | 25 |

| Concrete Mixer | Solar panels, Waste recycling | 7 | Construction, Concrete production | 20 |

| Paver | Low emissions technology | 8 | Road construction | 28 |

| Crane | Telematics system, Load optimization | 9 | Heavy lifting, Load transfer | 40 |

Future Trends: AI and Automation in Infrastructure Development

As we delve into the future of infrastructure development, the integration of AI and automation stands out as a pivotal force. In 2019, the global intelligent robotics market was valued at $5.98 billion, and projections indicate it could reach $31.1 billion by 2027, showcasing a compound annual growth rate of 23.1%. This rapid growth illustrates the profound impact that AI technologies will have on the civil engineering landscape.

One notable trend in AI's application is the use of digital twin technology. By leveraging this advanced simulation and high-resolution modeling, engineers can identify and refine manufacturing processes with unparalleled accuracy. This innovative approach not only enhances product design but also facilitates more efficient project management, driving a shift toward smarter infrastructure solutions.

**Tips for Embracing AI in Infrastructure:**

1. **Invest in Training:** Ensure that your team is well-versed in AI and automation technologies. Continuous learning will be crucial as these tools evolve.

2. **Prioritize Collaboration:** Foster an environment where human experts work alongside AI systems. This collaboration can lead to more innovative solutions and improved decision-making.

3. **Stay Updated on Trends:** Keep an eye on emerging technologies and their applications in civil engineering. Adapting early to these trends can provide a competitive edge in the market.

Challenges and Solutions in Adopting New Engineering Machines

As the landscape of civil engineering evolves, the integration of advanced machines presents both challenges and opportunities. A recent report from the International Journal of Engineering Management highlighted that the global construction equipment market is projected to reach $350 billion by 2025, showing a robust increase driven by the demand for modern infrastructure solutions. However, the adoption of these new machines often encounters obstacles such as high initial costs, the need for specialized training, and adaptation to new technologies. Addressing these challenges requires a strategic approach from firms and stakeholders.

**Tip:** Invest in comprehensive training programs for your team to ensure they are well-equipped to handle new machinery efficiently. This not only enhances productivity but also mitigates safety risks associated with unfamiliar equipment.

Furthermore, data from the Construction Industry Institute indicates that projects utilizing innovative machinery see a 20% reduction in completion time. To fully harness these advancements, firms must also focus on developing effective communication channels that facilitate the sharing of best practices among teams. This cooperation can significantly lower entry barriers to new technologies and ensure that all stakeholders are on the same page concerning project goals.

**Tip:** Foster a culture of collaboration where feedback on new technologies is routinely gathered. Encouraging team members to share their experiences can lead to more effective implementation strategies and drive continuous improvement.

The Evolution of Civil Engineering Machines Shaping Tomorrow's Infrastructure

This chart illustrates the percentage of civil engineering projects using new machines over the last decade, highlighting the adoption trends and challenges faced within the industry.

Related Posts

-

Comparative Analysis of Civil Engineering Machines Efficiency in Modern Construction Projects

-

Innovative Applications of Best Mechanical Engineering Tech in Modern Industries

-

Ultimate Checklist for Achieving Best CNC Precision Engineering Excellence

-

Ultimate Guide to Selecting the Best Motor Mechanical Engineering Solutions for Global Buyers

-

The Future of Best Mechanical Manufacturing Innovations and Trends

-

China's Quality Evolution in Automotive Mechanical Engineering Driving Global Demand