Exploring Innovative Alternatives in Machine Engineering for Enhanced Efficiency and Productivity

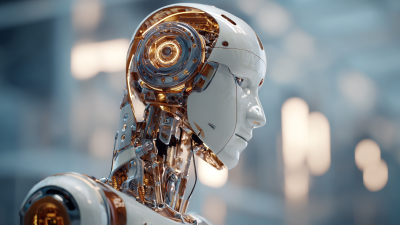

In the ever-evolving field of machine engineering, innovative alternatives are paramount for driving efficiency and productivity in manufacturing processes. According to a recent report by McKinsey, the integration of advanced technologies such as artificial intelligence and automation in machine engineering has the potential to boost productivity by up to 30%. Furthermore, a study from the International Federation of Robotics indicates that companies adopting these innovations are experiencing significant reductions in operational costs, often by as much as 20%. As industries seek to optimize their workflows and enhance economic output, exploring creative solutions within machine engineering becomes crucial. This blog will delve into various innovative strategies and tools that can propel organizations towards achieving superior efficiency and productivity, ultimately ensuring their competitive edge in the marketplace.

Identifying the Need for Innovation in Machine Engineering Practices

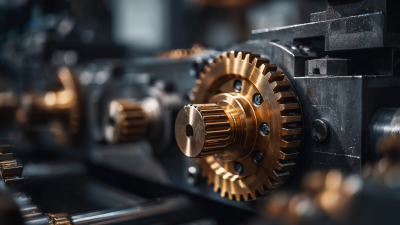

In the rapidly evolving landscape of machine engineering, the need for innovation has never been more crucial. Traditional practices often lead to inefficiencies, restricting productivity and ultimately hindering growth. To thrive in this competitive environment, engineers and organizations must embrace new methodologies that not only streamline processes but also enhance the overall effectiveness of their operations.

One innovative approach is adopting smart technologies, such as IoT and AI, which can significantly improve data collection and analysis. By leveraging real-time insights, engineers can make informed decisions, optimize workflows, and predict maintenance needs before issues arise. Tips for implementing smart technologies include starting with a pilot project to assess feasibility and gradually scaling up based on the results.

Another effective strategy is fostering a culture of collaboration and continuous learning within teams. Encouraging employees to share ideas and explore unconventional solutions can lead to breakthrough innovations. Team-building workshops and cross-disciplinary collaborations are excellent ways to inspire creativity. Remember to regularly gather feedback to refine engineering practices—this iterative approach ensures that the innovations align with both market demands and internal capabilities.

Current Trends in Alternative Technologies for Enhanced Productivity

The landscape of machine engineering is undergoing a transformative shift as companies increasingly explore alternative technologies to boost efficiency and productivity. According to a recent report by Deloitte, 63% of manufacturers are already incorporating automation and robotics into their operations, a trend that continues to gain momentum. These technologies are not only streamlining production processes but also allowing for greater precision and reduced error rates, ultimately leading to higher output levels.

In addition to automation, advancements in additive manufacturing, or 3D printing, are playing a pivotal role in enhancing productivity. A study by Wohlers Associates reveals that the additive manufacturing market is projected to grow to $35 billion by 2024, reflecting a compound annual growth rate (CAGR) of 25.76%. This growth is largely driven by the technology's ability to reduce material waste and produce complex components rapidly, demonstrating a significant improvement over traditional manufacturing methods. By embracing these innovative alternatives, industries are not just adapting to current trends but are also setting the stage for more sustainable and efficient manufacturing practices.

Exploring Innovative Alternatives in Machine Engineering for Enhanced Efficiency and Productivity

| Technology | Description | Efficiency Gain (%) | Adoption Rate (%) | Projected Impact on Productivity |

|---|---|---|---|---|

| 3D Printing | Additive manufacturing process that allows rapid prototyping. | 30 | 45 | Enables custom parts production and reduces waste. |

| IoT in Manufacturing | Integration of IoT devices to monitor machine performance. | 25 | 60 | Enhances predictive maintenance, reducing downtime. |

| Robotics Automation | Use of robots for repetitive tasks to increase speed and accuracy. | 40 | 55 | Significantly reduces labor costs and improves consistency. |

| Virtual Reality (VR) | Training simulations for machine operation and maintenance. | 35 | 25 | Reduces training time and enhances learning retention. |

| Energy-Efficient Motors | Motors designed for lower energy consumption and higher output. | 20 | 70 | Decreases operating costs and improves sustainability. |

Evaluating the Impact of Automation on Efficiency in Machine Engineering

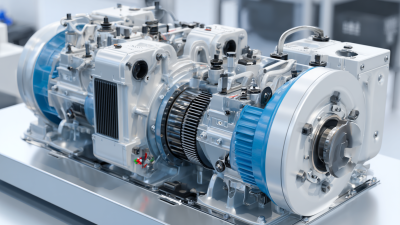

Automation has revolutionized the field of machine engineering, significantly enhancing efficiency and productivity. By integrating advanced technologies such as robotics, machine learning, and artificial intelligence, engineers can streamline production processes and reduce operational costs. Automated systems minimize human error and ensure consistency across manufacturing tasks, leading to higher quality outputs. Furthermore, machines equipped with real-time monitoring capabilities can assess their performance dynamically, allowing for proactive maintenance and reducing downtime.

Automation has revolutionized the field of machine engineering, significantly enhancing efficiency and productivity. By integrating advanced technologies such as robotics, machine learning, and artificial intelligence, engineers can streamline production processes and reduce operational costs. Automated systems minimize human error and ensure consistency across manufacturing tasks, leading to higher quality outputs. Furthermore, machines equipped with real-time monitoring capabilities can assess their performance dynamically, allowing for proactive maintenance and reducing downtime.

The impact of automation extends beyond mere efficiency; it fosters innovation within machine engineering itself. As repetitive tasks become automated, engineers can redirect their focus towards more complex problem solving and creative design. This shift not only accelerates product development cycles but also enables companies to respond swiftly to market demands. Additionally, the data collected from automated systems provides valuable insights into production processes, helping engineers identify bottlenecks and optimize workflows further. As automation continues to evolve, it promises to unlock new potentials in machine engineering, setting the stage for unprecedented advancements in productivity and efficiency.

Integrating Sustainable Practices in Machine Engineering Solutions

In the rapidly evolving field of machine engineering, integrating sustainable practices is crucial for fostering efficiency and productivity. Standing at the intersection of technology and environmental stewardship, innovative approaches emphasize the use of eco-friendly materials and energy-efficient processes. By prioritizing sustainability, engineers can significantly reduce waste and resource consumption, contributing to a circular economy that benefits both the industry and the planet.

Implementing such sustainable practices also enhances operational resilience and access to new markets that prioritize eco-conscious products. Companies that embrace these methods are not just improving their efficiency; they are also fortifying their brand reputation in a world increasingly aware of environmental impacts. As machine engineering continues to advance, the commitment to sustainability will be a defining factor in determining future leaders in the industry.

Case Studies: Successful Implementation of Innovative Machine Engineering Alternatives

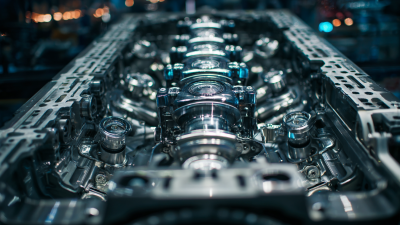

In the ever-evolving field of machine engineering, innovative alternatives have emerged that significantly enhance both efficiency and productivity. A notable case study involves a manufacturing company that implemented additive manufacturing techniques to streamline its production process. By using 3D printing technology, the company reduced material waste and minimized lead times, allowing for a more agile response to market demands. This shift not only cut costs but also improved the overall quality of their products, showcasing the potential of innovative methods in traditional manufacturing settings.

Another compelling example can be seen in the use of autonomous robotics in assembly lines. One automotive manufacturer integrated robotic systems that leverage AI for tasks such as quality inspection and component assembly. This implementation not only increased production speed but also allowed human workers to focus on more complex and creative tasks. The seamless collaboration between human expertise and robotic efficiency demonstrates how innovative machine engineering alternatives can transform traditional workflows and lead to substantial improvements in productivity.

Exploring Innovative Alternatives in Machine Engineering for Enhanced Efficiency and Productivity

Related Posts

-

Maximizing Savings with Superior After Sales Support for Best Mechanical Electrical Solutions

-

The Future of Best Mechanical Manufacturing Innovations and Trends

-

Top Trends in Best Machine Engineering: What to Expect in 2025

-

Unveiling Secrets to Source Premium Suppliers in Best Machine Engineering

-

The Ultimate Guide to Discovering the Best Engineering Solutions for Your Business Needs

-

China's Quality Evolution in Automotive Mechanical Engineering Driving Global Demand