Addressing the Key Challenges in the Performance of Civil Engineering Machines: A Data-Driven Approach

In the rapidly evolving field of civil engineering, the performance of civil engineering machines plays a crucial role in ensuring project efficiency and effectiveness. However, various challenges persist, hindering their optimal use. This blog will explore a data-driven approach to address these key challenges by utilizing advanced analytics and innovative technologies. By harnessing vast amounts of operational data, we can identify performance bottlenecks, predict maintenance needs, and optimize machine utilization.

Additionally, we will provide practical tips and strategies for civil engineers to enhance the performance of their machines, ultimately leading to increased productivity and reduced costs. Join us as we delve into the intersection of data analysis and civil engineering machinery, paving the way for smarter construction practices in the future.

Identifying Major Performance Challenges in Civil Engineering Machines

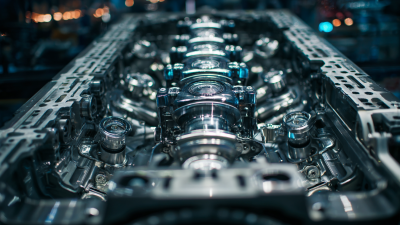

In the realm of civil engineering, machines play a pivotal role in the successful execution of projects. However, several performance challenges can hinder their efficiency and effectiveness. Among these challenges, issues such as equipment reliability, maintenance delays, and operating efficiency often arise. For instance, unplanned downtime due to equipment failure can significantly prolong project timelines and inflate costs.

Identifying these major hurdles is crucial for enhancing the productivity of civil engineering machines and ensuring the smooth flow of operations on construction sites.

A data-driven approach can be instrumental in pinpointing these key performance challenges. By leveraging advanced analytics and real-time monitoring, engineers can collect valuable data on machine performance, usage patterns, and maintenance needs. This information allows for a proactive response to potential issues before they escalate into major problems.

Furthermore, integrating predictive maintenance strategies can minimize unexpected breakdowns and optimize machine utilization, creating a more streamlined workflow. Ultimately, addressing these performance challenges through data insights not only improves the operational lifespan of machines but also ensures that civil engineering projects are completed on time and within budget.

Utilizing Data Analytics for Enhanced Machine Performance Monitoring

In the rapidly evolving field of civil engineering, data analytics has emerged as a critical tool for enhancing machine performance monitoring. By harnessing vast amounts of data generated from construction equipment, engineers can gain valuable insights into the operational efficiency of their machinery. This approach allows for real-time tracking of performance metrics, identifying patterns and potential issues that could hinder productivity.

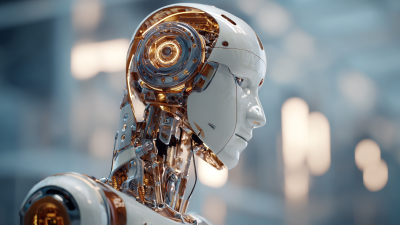

Utilizing advanced data analytics techniques, such as predictive maintenance and machine learning algorithms, organizations can preemptively address potential failures before they lead to costly downtimes. For instance, analyzing vibration data from heavy machinery can indicate wear and tear, prompting timely maintenance actions that extend the lifespan of equipment. Furthermore, visualizing operational data through dashboards enables project managers to make informed decisions, optimizing resource allocation while enhancing overall project delivery times.

The integration of data-driven approaches not only maximizes machine performance but also fosters a culture of continuous improvement within civil engineering practices. By embracing these analytical tools, companies can stay ahead in a competitive market, ensuring that their machines operate at peak performance while reducing operational costs and improving safety measures on site.

Implementing Predictive Maintenance to Reduce Downtime and Costs

In the realm of civil engineering, machine performance is often hindered by unexpected failures and downtime. Implementing predictive maintenance stands out as a solution that not only enhances performance but also significantly reduces costs associated with repairs and delays. By utilizing advanced data analytics, engineers can predict potential failures before they occur, allowing for timely interventions and maintenance scheduling.

Tip: Regularly collect data from machinery sensors to monitor operational health. This data can help create predictive models that forecast equipment performance and identify trends that may indicate wear or potential issues.

Furthermore, integrating machine learning algorithms can refine the predictive maintenance process. These algorithms analyze historical performance data to improve the accuracy of forecasts and help in making informed decisions about when and how to maintain equipment.

Tip: Establish a maintenance routine that includes both data analysis and physical inspections. Combining these approaches can lead to a holistic view of equipment health and operational efficiency.

By embracing a data-driven approach to predictive maintenance, civil engineering companies can not only minimize downtime but also optimize maintenance budgets, ensuring smoother project timelines and better resource allocation.

Leveraging IoT Sensors for Real-Time Performance Data Collection

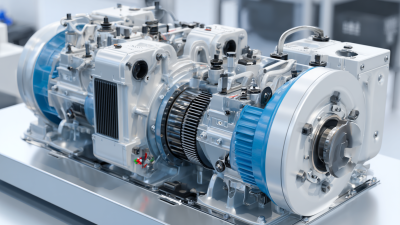

In the realm of civil engineering, the performance of machinery is paramount for successful project execution. To effectively monitor and enhance this performance, leveraging IoT sensors has emerged as a game-changing strategy. These sensors facilitate real-time data collection, offering insights into the operational status of equipment, which can significantly reduce downtime and maintenance costs. By continuously tracking metrics such as temperature, vibrations, and operational efficiency, project managers can make informed decisions that optimize machine use and longevity.

Moreover, the integration of IoT technology enables seamless communication between machines and central management systems. This connectivity allows for immediate alerts regarding any anomalies, ensuring that potential issues are addressed proactively. Data analytics tools can analyze the extensive information gathered, helping engineers identify patterns and trends that inform future machinery purchases or upgrades. As a result, embracing IoT sensors not only fosters an environment of proactive management but also enhances the overall performance and reliability of civil engineering machines, paving the way for more efficient project delivery.

Case Studies: Successful Data-Driven Solutions in Civil Engineering Machines

In the realm of civil engineering, the performance of machines can significantly impact project outcomes. By embracing a data-driven approach, engineers have successfully tackled numerous challenges associated with equipment efficiency and reliability. One notable case study is the implementation of predictive maintenance systems in heavy machinery. By utilizing real-time data analytics, companies can monitor equipment health, predict failures, and schedule maintenance proactively. This not only minimizes downtime but also extends the life of the machinery, ultimately leading to more cost-effective project management.

Another compelling example is the use of telematics in construction vehicles. These systems collect data on machine performance, fuel consumption, and operational patterns. As a result, project managers can optimize the usage and allocation of equipment based on actual performance metrics. One construction firm reported a 15% reduction in fuel costs after implementing a telematics solution, showcasing the potential benefits of data-driven decision-making in civil engineering operations. These case studies exemplify how data-driven solutions can lead to improved efficiency and effectiveness in civil engineering machinery, reshaping the industry for the better.

Addressing the Key Challenges in the Performance of Civil Engineering Machines: A Data-Driven Approach

| Machine Type | Performance Issue | Data-Driven Solution | Outcome |

|---|---|---|---|

| Excavator | Frequent Breakdowns | Predictive Maintenance through IoT Sensors | Reduction in Downtime by 30% |

| Concrete Mixer | Inconsistent Mix Quality | Real-time Quality Monitoring with AI | Improved Quality Consistency by 40% |

| Bulldozer | Fuel Efficiency Issues | Data Analytics for Fuel Consumption | Enhanced Fuel Efficiency by 15% |

| Paver | Surface Finish Problems | Automated Surface Monitoring | Reduced Surface Defects by 25% |

Related Posts

-

Top Strategies for Maximizing Efficiency with Best Civil Engineering Machines

-

Comparative Analysis of Civil Engineering Machines Efficiency in Modern Construction Projects

-

Maximizing Savings with Superior After Sales Support for Best Mechanical Electrical Solutions

-

Ultimate Guide to Selecting the Best Motor Mechanical Engineering Solutions for Global Buyers

-

Top Trends in Best Machine Engineering: What to Expect in 2025

-

China's Quality Evolution in Automotive Mechanical Engineering Driving Global Demand