Why Engineering Solutions Are Vital for Reducing Project Costs by Up to 30 Percent

In the competitive landscape of project management, finding innovative ways to cut costs without compromising quality is essential for success. Engineering solutions play a crucial role in this endeavor, offering strategic methods to streamline processes and increase efficiency. By integrating advanced engineering principles and practices, organizations can achieve significant reductions in project expenses—often by as much as 30 percent. This "how to" guide will explore various engineering solutions that can be implemented across different phases of a project, from planning and design to execution and completion. By leveraging these solutions, project managers not only enhance their resource allocation but also foster a culture of continuous improvement, ultimately leading to more sustainable and profitable outcomes. Embracing engineering solutions is not just an option; it is a vital strategy for those seeking to navigate the complexities of modern project demands.

The Role of Engineering Solutions in Cost Management

Engineering solutions play a crucial role in effective cost management throughout the lifecycle of a project. By adopting innovative design techniques and leveraging advanced technologies, engineering teams can identify potential inefficiencies early in the planning phases. This proactive approach allows for adjustments that can lead to significant cost reductions. For instance, utilizing simulation models can optimize resource allocation and streamline processes, which directly impact overall expenses.

Moreover, engineering solutions facilitate better collaboration among project stakeholders. By integrating engineering insights into project management tools, teams can achieve greater visibility into project timelines and budgets. This transparency helps in making informed decisions that can mitigate risks and anticipate future challenges. As a result, the ability to respond swiftly to changes not only improves project efficiency but also contributes to a potential reduction in costs by up to 30 percent, making engineering a vital component in contemporary project management strategies.

Key Strategies for Implementing Efficient Engineering Practices

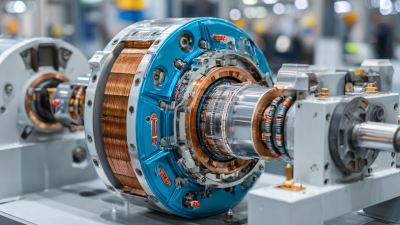

Efficient engineering practices are crucial for reducing project costs, with studies indicating that organizations can save up to 30 percent by streamlining their engineering processes. In the construction industry, for example, the nominal value added increased by 10% in 2024, suggesting robust growth driven by effective engineering strategies. Implementing practices such as Site Reliability Engineering (SRE) not only enhances system reliability but also turns technical efficiencies into measurable business assets that can catalyze cost reduction.

Key strategies to achieve these efficiencies include optimizing material use through advanced computational tools, which can mitigate barriers like lack of awareness and perceived costs. By adopting a strategic roadmap for implementing SRE practices, companies can automate workflows and align their engineering processes with business goals. Moreover, as organizations navigate the evolving landscape of AI technology, effective context engineering can further enhance operations, ensuring that teams leverage the full potential of their engineering practices to drive down costs and improve overall project outcomes.

Quantifying Cost Reductions through Advanced Engineering Techniques

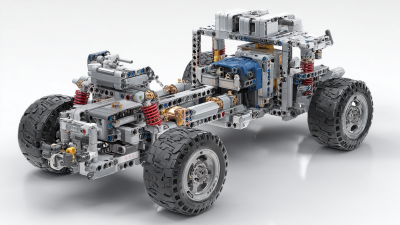

Advanced engineering techniques have emerged as crucial tools in optimizing project costs across various industries. According to a report by McKinsey & Company, projects that incorporate innovative engineering designs and methods can achieve cost savings of up to 30%. This efficiency is primarily due to techniques such as modular construction, predictive analytics, and leveraging advanced materials, which streamline processes and reduce waste.

For example, in the construction sector, the use of prefabricated components can reduce on-site labor time and minimize material waste, leading to significant cost reductions.

For example, in the construction sector, the use of prefabricated components can reduce on-site labor time and minimize material waste, leading to significant cost reductions.

Moreover, the application of data-driven engineering solutions enables real-time monitoring and adjustments, further driving efficiency. A study published by the Project Management Institute indicates that organizations employing advanced analytics during project planning and execution can decrease their budget overruns by as much as 25%.

By quantifying the impact of these engineering techniques, companies not only enhance the overall quality of their projects but also ensure that they remain within financial constraints, fostering a more sustainable approach to project management in a competitive economic landscape.

Case Studies: Successful Engineering Solutions in Project Cost Reduction

Engineering solutions play a crucial role in streamlining project processes and significantly reducing costs. According to a study by McKinsey & Company, effective use of engineering practices can lead to cost reductions of up to 30% in construction and infrastructure projects. For instance, the use of advanced modeling techniques and prefabrication solutions has been reported to decrease project lead times and eliminate unnecessary labor costs. In one case, a large infrastructure project in the U.S. incorporated 3D modeling and prefabrication, which resulted in a 25% reduction in overall project costs while enhancing quality and safety conditions.

Engineering solutions play a crucial role in streamlining project processes and significantly reducing costs. According to a study by McKinsey & Company, effective use of engineering practices can lead to cost reductions of up to 30% in construction and infrastructure projects. For instance, the use of advanced modeling techniques and prefabrication solutions has been reported to decrease project lead times and eliminate unnecessary labor costs. In one case, a large infrastructure project in the U.S. incorporated 3D modeling and prefabrication, which resulted in a 25% reduction in overall project costs while enhancing quality and safety conditions.

Moreover, the benefits of innovative engineering solutions extend beyond just immediate savings. A report from the American Society of Civil Engineers highlights that projects that employ integrated project delivery methods and collaborative engineering techniques tend to complete under budget 60% of the time compared to traditional methods. A notable example can be seen in a California highway expansion project, where the adoption of lean construction principles, including just-in-time delivery and modular design, led to a remarkable 30% decrease in costs. This not only saved money but also minimized waste and improved efficiency across the board, showcasing the transformative impact engineering solutions can have on project management and execution.

Future Trends in Engineering That Promise Further Cost Savings

As engineering continues to evolve, several future trends are emerging that promise significant cost savings for projects. One of the most impactful developments is the integration of advanced technologies such as artificial intelligence and machine learning into engineering processes. These technologies streamline design and analysis phases, enabling engineers to identify potential issues earlier and optimize resource allocation. By predicting project outcomes more accurately, firms can avoid costly delays and rework, ultimately driving down project costs.

Another promising trend is the rise of modular and off-site construction techniques. This approach allows for components to be manufactured in a controlled environment, reducing waste and improving quality. By assembling structures more efficiently on-site, projects can see reduced labor costs and time savings. Moreover, incorporating sustainable materials and practices not only enhances a project’s environmental footprint but also cuts costs associated with materials handling and disposal. Collectively, these innovations are set to revolutionize the engineering landscape, ensuring that cost efficiency remains at the forefront of project management strategies.

Why Engineering Solutions Are Vital for Reducing Project Costs by Up to 30 Percent - Future Trends in Engineering That Promise Further Cost Savings

| Cost Reduction Strategy | Estimated Cost Savings (%) | Implementation Timeframe | Future Trends |

|---|---|---|---|

| Modular Construction | 20% | 6-12 months | Increased efficiency through prefabrication |

| Building Information Modeling (BIM) | 25% | 3-6 months | Enhanced collaboration and accuracy |

| 3D Printing | 15% | 1-2 months | Customizable and reduced waste |

| Lean Construction | 30% | Ongoing | Focus on resource management |

| Automation and Robotics | 20% | 1-2 years | Increased precision and labor savings |

Related Posts

-

The Ultimate Guide to Discovering the Best Engineering Solutions for Your Business Needs

-

Innovative Applications of Best Mechanical Engineering Tech in Modern Industries

-

Addressing the Key Challenges in the Performance of Civil Engineering Machines: A Data-Driven Approach

-

Ultimate Guide to Mastering Automotive Mechanical Engineering for Future Innovators

-

What is the Impact of Mechanical and Electrical Engineering on Modern Industries

-

How to Navigate the World of Mechanical and Electrical Engineering Innovations