How to Succeed in Mechanical Manufacturing Best Practices and Tips for Beginners

In the evolving landscape of mechanical manufacturing, organizations face both challenges and opportunities that require a profound understanding of industry best practices. With a projected market growth from $2 trillion in 2020 to $3.5 trillion by 2025, mechanical manufacturing is witnessing an unprecedented transformation fueled by technological innovations and a surge in demand for high-quality production methods. According to the Global Manufacturing Outlook report, 76% of manufacturers believe that adopting smart technologies will significantly enhance their operational efficiency.

Expert in mechanical manufacturing, Dr. John Harrison, emphasizes the importance of adaptability in this competitive field, stating, "To thrive in mechanical manufacturing, one must not only master the craft but also embrace change by continuously evolving processes and technologies." This perspective underlines the necessity for beginners to focus not only on foundational skills but also on the integration of modern practices and technologies. The journey to success in this domain involves tapping into the vast resources available through industry insights, continuous learning, and networking within the manufacturing community. By understanding and implementing the best practices in mechanical manufacturing, aspiring professionals can position themselves for significant advancements in their careers while contributing to the industry's growth.

Understanding the Basics of Mechanical Manufacturing Processes

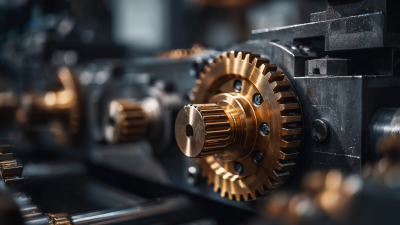

Understanding the fundamentals of mechanical manufacturing is crucial for beginners embarking on a career in this dynamic field. Mechanical manufacturing encompasses various processes, including machining, welding, casting, and additive manufacturing, each pivotal in creating precision components for different industries. According to a report by the National Association of Manufacturers, the U.S. manufacturing sector contributed over $2.3 trillion to the economy in 2021, showcasing the vital role of these processes in driving economic growth and innovation.

Newcomers should familiarize themselves with essential concepts such as tolerances, materials selection, and process optimization. For instance, understanding geometric dimensioning and tolerancing (GD&T) can help ensure that parts fit together correctly, which is critical in high-stakes applications like aerospace and automotive manufacturing. Recent data indicates that about 30% of manufacturing defects arise from improper tolerancing and geometric errors, highlighting the importance of precise specifications in reducing waste and enhancing product quality.

Additionally, gaining insight into lean manufacturing principles can significantly improve efficiency and decrease production costs. A study by the Lean Enterprise Institute found that companies implementing lean methodologies have realized productivity gains of 25% to 60% on average. By mastering these basic principles, beginners can establish a strong foundation that will aid in navigating the complexities of mechanical manufacturing and contribute to their long-term success in the industry.

Essential Tools and Equipment for Beginners in Mechanical Manufacturing

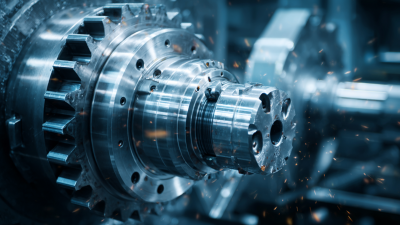

In mechanical manufacturing, having the right tools and equipment can significantly impact the efficiency and quality of your work. For beginners, understanding the essential tools required is crucial to building a strong foundation in this field. A basic toolkit should include measuring instruments such as calipers and micrometers for accurate dimensions, as well as hand tools like wrenches, screwdrivers, and pliers for assembly and disassembly tasks. Additionally, a reliable set of cutting tools such as saws and drill bits is necessary for shaping and modifying materials.

Another key aspect of mechanical manufacturing is the use of machinery, which can elevate your projects from simple to complex. A milling machine is a versatile piece of equipment that allows for precise cutting and shaping of materials. Furthermore, a lathe is invaluable for creating cylindrical parts, enabling smooth rotations and detailed designs. Beginners should also consider investing in safety equipment, including goggles and gloves, to ensure protection while operating machinery. By familiarizing yourself with these essential tools and equipment, you will set the stage for a successful journey in mechanical manufacturing.

Best Practices for Quality Control in Manufacturing Environments

In the realm of mechanical manufacturing, ensuring quality control is paramount for achieving operational excellence and customer satisfaction. Implementing effective best practices can significantly enhance the reliability and quality of products being manufactured. One of the core practices involves establishing a standardized operating procedure (SOP) that incorporates detailed checkpoints throughout the manufacturing process. This allows for consistent monitoring and validation of each production stage, ensuring that any deviations from the desired quality are promptly addressed.

**Tip:** Regular training sessions for employees on quality standards and expectations are vital. Providing workers with updated knowledge and skills enables them to identify potential quality issues early, fostering a proactive quality culture within the team.

Another critical aspect of quality control is the integration of comprehensive inspection methods. Utilizing tools such as Statistical Process Control (SPC) can help in analyzing variations during production and understanding when processes are drifting away from set limits. By systematically collecting data from manufacturing operations, teams can make informed adjustments, enhancing the overall quality of the output.

**Tip:** Leverage technology like automated inspection systems or quality monitoring software to streamline the process. These tools can improve accuracy, reduce human error, and allow for real-time adjustments, making quality control more efficient and effective.

Effective Time Management Techniques in Mechanical Manufacturing

Effective time management is crucial for success in mechanical manufacturing, especially for beginners navigating this complex field. By implementing strategic techniques, individuals can enhance productivity and ensure that projects are completed efficiently. One of the best practices is to prioritize tasks based on urgency and importance, employing the Eisenhower Matrix as a tool. This approach allows individuals to focus on high-priority tasks while minimizing time spent on less critical activities, ensuring that essential deadlines are met.

Another effective technique is to utilize time-blocking strategies. By allocating specific blocks of time to different tasks, individuals can create a structured work environment that fosters concentration and reduces the likelihood of distractions. This method not only helps in maintaining focus but also encourages a systematic approach to project management. Additionally, incorporating regular breaks into the schedule can improve overall productivity by preventing burnout and enhancing creativity. Through these strategies, beginners in mechanical manufacturing can effectively manage their time, leading to improved outcomes in their projects and professional growth.

Mechanical Manufacturing Effective Time Management Techniques

Strategies for Continuous Improvement and Skill Development in Manufacturing

Continuous improvement and skill development are crucial in the modern landscape of mechanical manufacturing. One effective strategy for fostering these elements is the implementation of Lean Manufacturing principles. Lean focuses on minimizing waste and maximizing efficiency, which can lead to substantial cost savings and enhanced productivity. By regularly assessing processes and identifying areas for improvement, manufacturers can create a culture of continuous enhancement. Training sessions and workshops that engage employees in Lean practices not only elevate their skill sets but also empower them to contribute to the optimization of production processes.

Another key aspect of skill development in manufacturing is the integration of technology and automation. Embracing advancements such as computer-aided design (CAD) and computer numerical control (CNC) machining can significantly enhance precision and efficiency. Providing employees with training on these technologies ensures they are equipped to operate advanced machinery and understand the complexities of modern manufacturing processes. Moreover, fostering an environment where employees are encouraged to pursue certifications and additional education can lead to higher job satisfaction and retention rates. By prioritizing both continuous improvement and skills enhancement, manufacturers can position themselves for long-term success in a competitive market.

How to Succeed in Mechanical Manufacturing Best Practices and Tips for Beginners - Strategies for Continuous Improvement and Skill Development in Manufacturing

| Practice | Description | Benefits | Tips |

|---|---|---|---|

| Lean Manufacturing | Eliminating waste to improve efficiency | Reduced costs, increased output | Focus on value-added activities |

| Six Sigma | Quality management method aimed at reducing defects | Improved product quality, customer satisfaction | Use data-driven approaches for decision making |

| Continuous Improvement (Kaizen) | Ongoing efforts to improve products and processes | Greater operational efficiency, employee engagement | Encourage employee feedback and suggestions |

| Training and Development | Investing in employee skills and knowledge | Enhanced skill sets, higher productivity | Provide regular workshops and hands-on training |

| Automation | Using technology to automate processes | Improved accuracy, reduced labor costs | Start with high-impact processes for automation |

Related Posts

-

How to Optimize Mechanical Manufacturing Efficiency Using Data Analytics Techniques

-

Unveiling Secrets to Source Premium Suppliers in Best Machine Engineering

-

Top Trends in Best Machine Engineering: What to Expect in 2025

-

Exploring Innovative Alternatives in Machine Engineering for Enhanced Efficiency and Productivity

-

Revolutionizing Mechanical Manufacturing: Innovations Driving Efficiency and Quality in Production

-

Understanding the Future of Mechanical Manufacturing in a Changing World