How to Optimize Mechanical Manufacturing Efficiency Using Data Analytics Techniques

In the rapidly evolving landscape of mechanical manufacturing, the integration of data analytics techniques has emerged as a game-changer for enhancing operational efficiency. According to a report by Deloitte, companies that leverage data analytics can improve their manufacturing productivity by up to 20%, highlighting the critical impact of analytics in driving performance improvements. As mechanical manufacturing processes become increasingly complex, the need for precise data-driven decision-making is paramount. By employing advanced analytics, organizations can identify inefficiencies, optimize supply chain management, and enhance quality control, resulting in significant cost savings and increased throughput. Furthermore, a study by McKinsey indicates that manufacturers adopting predictive analytics can reduce maintenance costs by 10-30% while minimizing downtime. This compelling evidence underscores the necessity for mechanical manufacturing firms to embrace data analytics techniques as a fundamental component of their operational strategy to achieve sustainable growth and competitive advantage.

Identifying Key Performance Indicators for Mechanical Manufacturing Efficiency

In the realm of mechanical manufacturing, identifying key performance indicators (KPIs) is crucial for optimizing efficiency. KPIs provide measurable objectives that help organizations track performance over time and identify areas needing improvement. According to a report by McKinsey, companies that effectively utilize data analytics can enhance their operational efficiency by up to 20% through informed decision-making and process optimization. Common KPIs in this sector include overall equipment effectiveness (OEE), cycle time, defect rates, and throughput, each offering insights into different facets of production performance.

**Tips**: Establish a baseline for each KPI to measure progress accurately. Use real-time data collection tools to monitor KPIs effectively and adjust processes accordingly. Regularly review and update your KPIs based on changing business goals and market conditions.

Moreover, leveraging data analytics tools can significantly enhance the ability to analyze these KPIs. A report by Deloitte indicated that manufacturing organizations integrating advanced analytics saw a productivity increase of 15-25%. By employing predictive analytics, manufacturers can foresee potential downtimes and streamline operations to ensure a more agile and responsive manufacturing process.

**Tips**: Implement predictive maintenance practices by analyzing machinery performance data to minimize downtime. Foster a culture of continuous improvement that encourages staff to contribute insights based on KPI analysis.

Mechanical Manufacturing Efficiency Metrics

Leveraging Big Data for Enhanced Decision-Making in Manufacturing Processes

In the modern manufacturing landscape, leveraging big data is becoming crucial for enhancing decision-making processes. A report by McKinsey reveals that data analytics can improve productivity by 20-30% when applied effectively in manufacturing environments. By analyzing real-time production data, companies can optimize resource allocation, reduce downtime, and streamline operations. This not only drives efficiency but also leads to cost savings and increased product quality.

Moreover, integrating big data analytics into manufacturing workflows enables businesses to anticipate equipment failures before they occur. The predictive maintenance approach can reduce maintenance costs by up to 25%, as cited in a study by Deloitte. By harnessing machine learning algorithms that analyze historical data patterns, manufacturers can make informed decisions about equipment servicing and replacement, ultimately enhancing operational efficiency. As organizations continue to embrace these technologies, the ability to convert actionable insights from data into strategic business outcomes will define the leaders in the manufacturing sector.

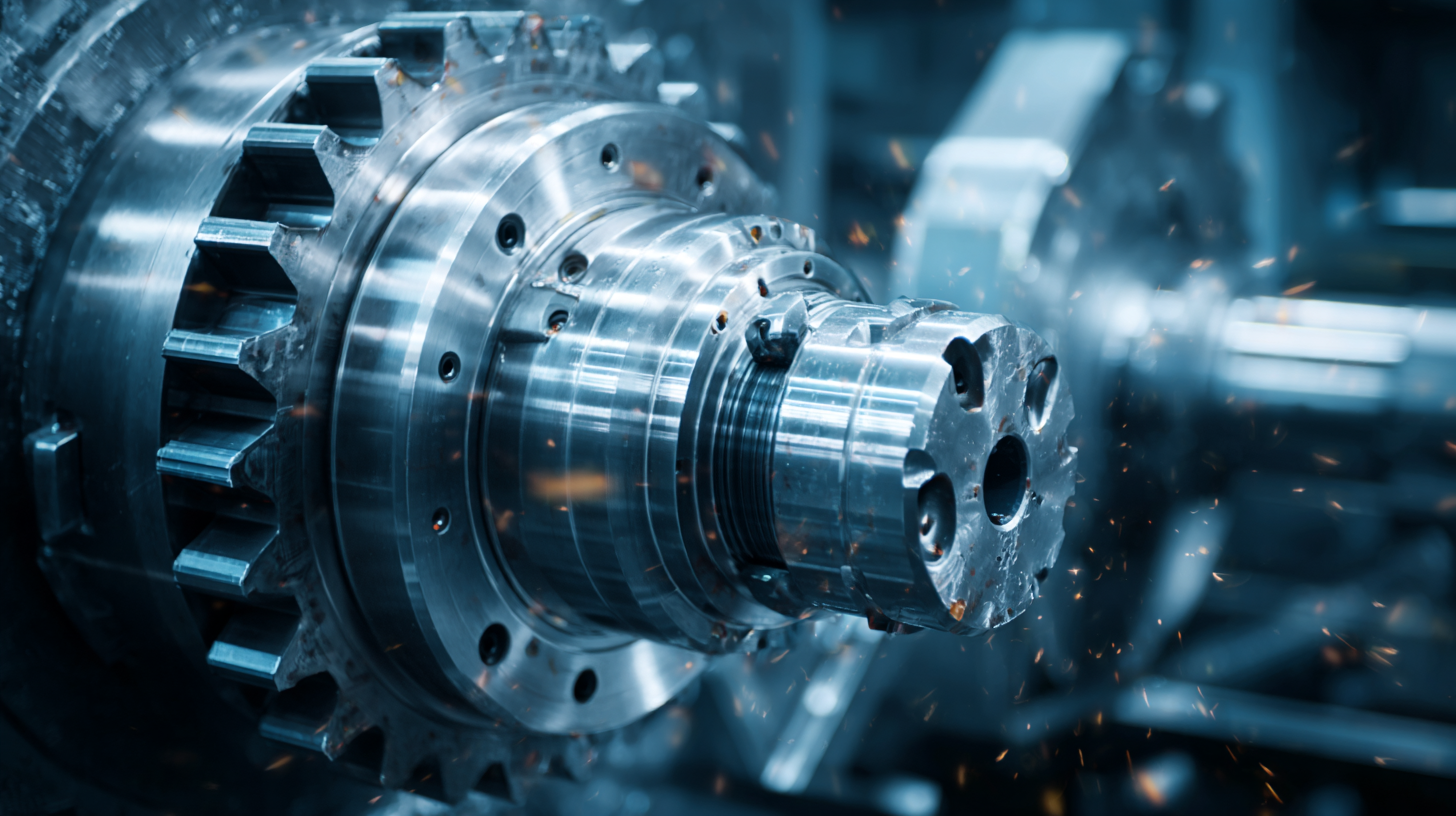

Implementing Predictive Maintenance Through Data Analytics Techniques

Predictive maintenance (PdM) is transforming the landscape of mechanical manufacturing by leveraging data analytics techniques to enhance operational efficiency. By collecting and analyzing equipment operating data, manufacturers can identify potential failures and trends in performance decline, leading to timely interventions. According to a report by the International Society of Automation (ISA), approximately 5% of factory production is lost annually due to unplanned downtime, equating to a staggering $647 billion in losses across various industries. Implementing effective PdM strategies is crucial, as they can significantly mitigate these losses.

Key strategies for advancing predictive maintenance include embracing advanced data modeling technologies and focusing on real-time data analytics. These approaches not only streamline maintenance schedules but also optimize inventory management and production workflows. As the telecom sector integrates AI-driven solutions for operational management, the ripple effect is evident across the manufacturing landscape. The growing reliance on data analytics is expected to contribute to substantial market growth, with projections indicating the global big data market in the power industry could rise from $11.16 billion in 2024 to $29.15 billion by 2032, reflecting a compound annual growth rate of 12.75%. This underscores the critical role of advanced analytics in fostering efficiency and innovation within the mechanical manufacturing sector.

| Machine ID | Operating Hours | Last Maintenance Date | Predicted Failure Date | Downtime (hours) | Efficiency (%) |

|---|---|---|---|---|---|

| M-001 | 2500 | 2023-09-15 | 2023-11-01 | 5 | 92 |

| M-002 | 3000 | 2023-08-20 | 2023-10-15 | 3 | 95 |

| M-003 | 2800 | 2023-10-01 | 2023-11-10 | 4 | 90 |

| M-004 | 2700 | 2023-09-10 | 2023-10-25 | 6 | 88 |

| M-005 | 3500 | 2023-08-30 | 2023-11-20 | 2 | 96 |

Utilizing Machine Learning to Optimize Production Schedules and Resource Allocation

In the realm of mechanical manufacturing, the application of machine learning techniques to optimize production schedules and resource allocation has emerged as a game-changer. According to a report by McKinsey, manufacturers that effectively leverage data analytics can enhance their productivity by 20-30%. Machine learning algorithms analyze vast amounts of operational data, identifying patterns and anomalies that human operators may overlook. By predicting machinery failures and maintenance needs, companies can reduce downtime and enhance equipment utilization, resulting in significant cost savings.

Moreover, the adoption of predictive analytics allows manufacturers to fine-tune their production schedules based on real-time demand forecasts. A study from the Aberdeen Group found that manufacturers using advanced analytics achieve a 10% increase in on-time delivery rates. By optimizing resource allocation through machine learning, firms can ensure that the right resources are available at the right time, minimizing waste and improving overall operational efficiency. This strategic shift not only streamlines production but also enhances supply chain resilience, making organizations better equipped to respond to fluctuations in market demand.

Visualizing Manufacturing Data for Improved Operational Insights and Strategies

In today's fast-paced manufacturing environment, visualizing data plays a crucial role in enhancing operational insights and strategies. By leveraging advanced data analytics techniques, manufacturers can transform raw data into comprehensive visual formats that highlight key performance indicators (KPIs) and operational bottlenecks. According to a report by Deloitte, organizations that implement data visualization solutions report a 25% increase in productivity within their manufacturing processes. This indicates a significant potential for operational improvements through effective data interpretation.

To maximize the benefits of data visualization, manufacturers should adopt a few best practices. First, utilize interactive dashboards to allow stakeholders to explore data in real time, making it easier to identify trends and anomalies. Additionally, implementing heat maps can provide a clear visual representation of machine performance, leading to more informed decision-making regarding maintenance schedules and resource allocation. Another tip is to integrate predictive analytics into visual tools, enabling manufacturers to forecast demand and optimize inventory levels effectively.

Investing in training for employees on data interpretation can also enhance the overall efficiency of manufacturing processes. A recent study indicated that companies prioritizing data literacy saw a 30% improvement in project outcomes. By fostering a culture of data-driven decision-making, manufacturers will be well-equipped to harness the power of their data, ultimately leading to improved efficiency and competitiveness in the industry.

Related Posts

-

Exploring Innovative Alternatives in Machine Engineering for Enhanced Efficiency and Productivity

-

Ultimate Checklist for Achieving Best CNC Precision Engineering Excellence

-

How to Choose the Right CNC Precision Engineering Solutions for Your Business Needs

-

What is the Impact of Mechanical and Electrical Engineering on Modern Industries

-

How to Enhance Your Supply Chain with Mechanical Engineering Tech Solutions

-

Maximizing Savings with Superior After Sales Support for Best Mechanical Electrical Solutions